Basic Info.

After-sales Service

Online Support, Video Technical Support

Model No.

M(Meltblown)

Structure Form

M(Meltblown)

Print Color

Following Customer′s Requirements

Output

3-4ton/Day

Speed

10-100m/Min

Transport Package

Wooden Case

Specification

3.2m

Trademark

Jinxin

Origin

Wenzhou

HS Code

8449009000

Production Capacity

10psc/Year

Product Description

Meltblown Nonwoven Fabric Making Machine

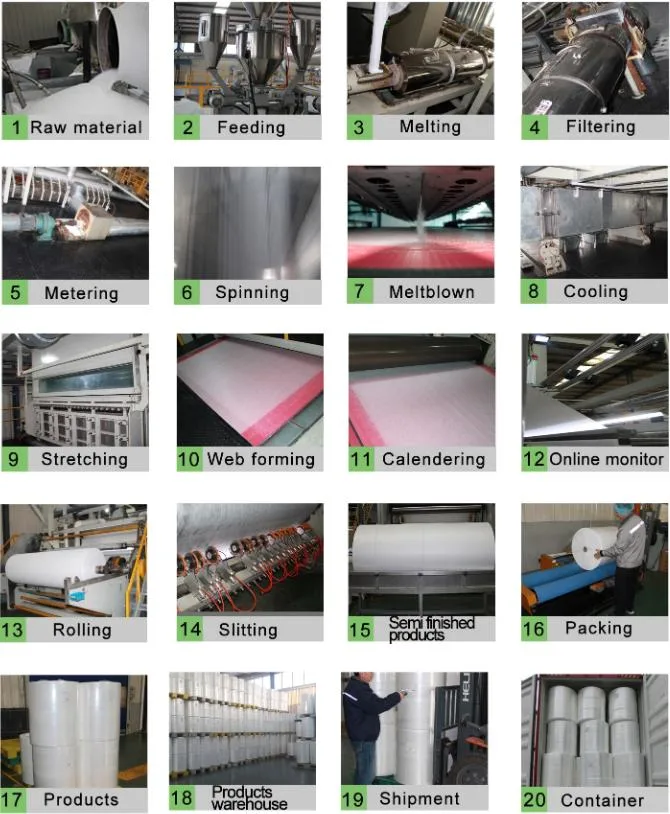

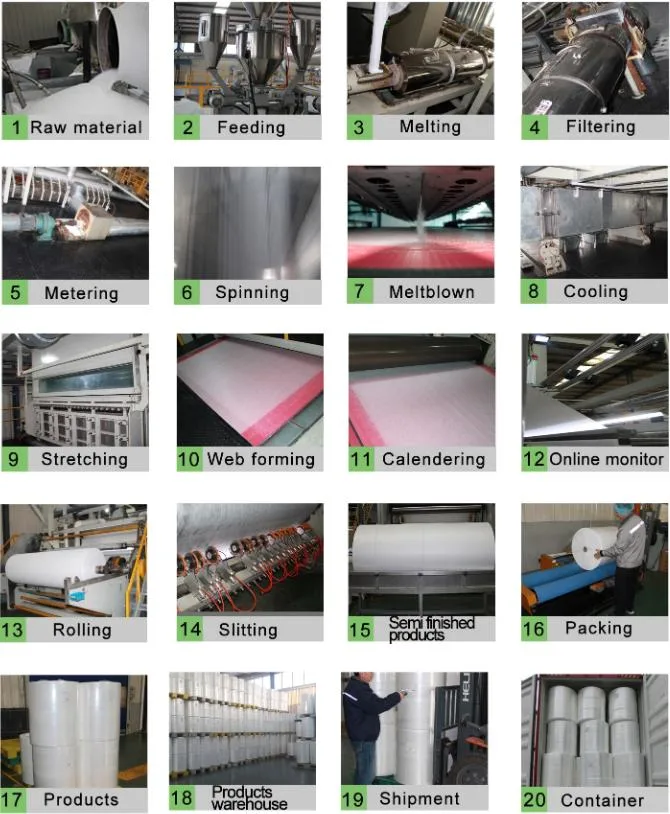

This equipment is used for the production of melt blown nonwoven fabric.

Different colors and functions of melt blown nonwovens are produced with polypropylene fiber as the main raw material, supplemented by Color Masterbatch, antioxidant, electrostatic electret, flame retardant and other additives.

The products are widely used in industrial felt, industrial oil absorbent cloth, industrial sound insulation cotton, industrial high efficiency filter material, etc. at the same time, the production line can also produce disposable ordinary melt blown cloth for mask and melt blown cloth for mask which can achieve N90 or above high efficiency by adding electret masterbatch and electrostatic electret treatment.

Technical data

Technical data

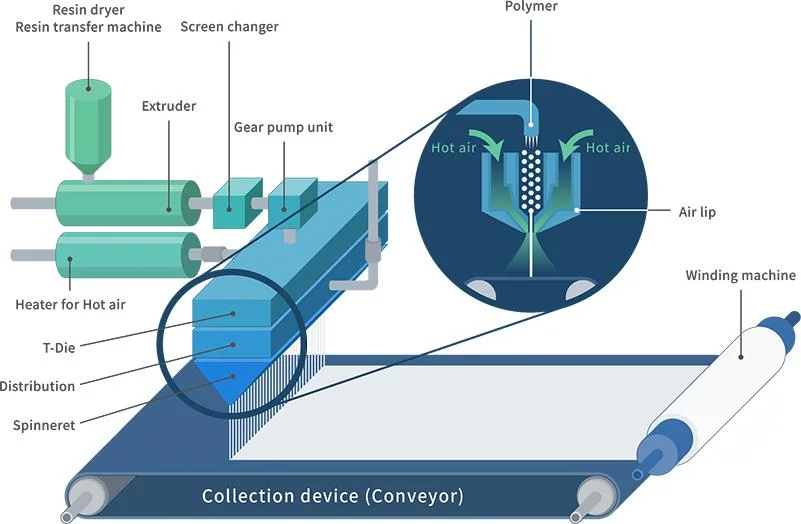

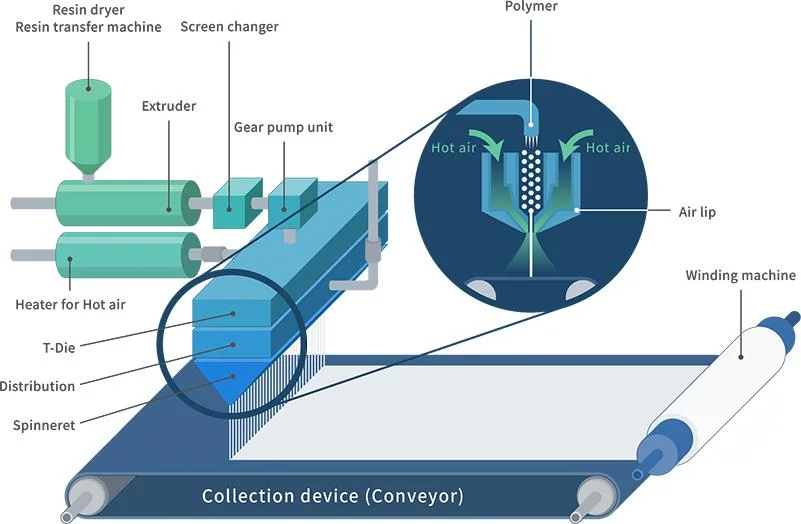

Machine Drawing

After Sale Service Terms:

Why choose us?

1. High standard nonwoven machine specification.

2. Free inspection invitation before delivery.

3. your order safe and your money is safe.

4. Free door to door engineering service in 24 month.

5. CE Certification and ISO:9001 management system.

FAQ:

This equipment is used for the production of melt blown nonwoven fabric.

Different colors and functions of melt blown nonwovens are produced with polypropylene fiber as the main raw material, supplemented by Color Masterbatch, antioxidant, electrostatic electret, flame retardant and other additives.

The products are widely used in industrial felt, industrial oil absorbent cloth, industrial sound insulation cotton, industrial high efficiency filter material, etc. at the same time, the production line can also produce disposable ordinary melt blown cloth for mask and melt blown cloth for mask which can achieve N90 or above high efficiency by adding electret masterbatch and electrostatic electret treatment.

| Type | JX-M-3.2 | ||

| M(Product width) | 3200mm | ||

| Equipment Size | 15*10*10m | ||

| Voltage | AC380V,50 Hz;power about 500KW | ||

| Speed | 100m/min | ||

| Gram Weight | 10-80g/m2 | ||

| Air pressure | Compressed air pressure 0.5-0.8MPa;Compressed air flow 500L/min | ||

| Output(according to 25g/m2) | 3-4T/Day | ||

| Finished product filtering efficiency | ≥99% | ||

| Features | ||||

| Dosing & metering system | Vacuum suction or blower feeding system. Gravimetric metering system with precise accuracy. Automatic alarm for high and low position limit. | |||

| Spinning beam | Single coat-hanger melt distribution, manufactured by 4-coordinates CNC, grinding by manual. | |||

| Quenching chamber | Several layers multistep honey plates with different size holes. Quenching air distribution is uniform and easier for dismounting and cleaning. | |||

| Stretching channel | Inside wall is made of polished stainless steel, top and bottom stretching channels can adjust slot width at the same time. | |||

| Diffusing channel | Channel is made of stainless steel. Special forming process and welding technology guarantee the whole channel is flat and no shape changing. | |||

| Conveyor | Rollers are inspected by dynamic balance to guarantee running in stable situation. Surface of prepressing roller is coated by ceramic, to prevent entanglement. MB system has pneumatic belt protection unit. | |||

| Meltblown system | Imported screw blower has been applied to create stretching air. Pressure is constant, Spinning pressure is lower, higher efficiency and less power consumption. | |||

| Electrical control system | The whole machine is controlled by PLC, AC inversion motor for the whole synchronization system, The process parameters and fault can be displayed and alarmed. The whole system is in stable and reliable situation. | |||

After Sale Service Terms:

- Installation: the Seller will despatch 4-5 engineers for installation and commission of the production line, training the Buyer's workers in the site. Normally it will take 1 month for whole installation and training.

- Cost: the Seller should cover the engineers' salary, visa cost and round air tickets. However, the Buyer should cover the accommodations, transportation, food and other related cost occurring in Buyer's country. Also, the Buyer should prepare enough labor, electric wire and cables outside of the control panel and tools for installation.

- Machine Guarantee: 2 years within 1 year free spare parts;

- Guarantee Period: 24 months after the completion of commission but not later than 28 months after the shipping (BL) date. In case any item proves to be defective and the damage is confirmed by Seller's technicians within this period, the Seller will send engineer to repair or supply a new one for replacement free of charge on the basis of CNF delivery.

- Guarantee Parts: the above items do not include the parts, which are among regular spares and easily-damaged parts from normal wear, abnormal operation, improper maintenance and inadequate civil works.The seller will be not responsible for any production loss under any circumstances.

Why choose us?

1. High standard nonwoven machine specification.

2. Free inspection invitation before delivery.

3. your order safe and your money is safe.

4. Free door to door engineering service in 24 month.

5. CE Certification and ISO:9001 management system.