- Overview

- Product Description

- Customer Sites

- Customer Visiting

Basic Info.

Product Description

Brief Introduction of Filter Press

Filter press is a mechanical device used for solid-liquid separation. It uses mechanical pressure to press out the solids in the liquid and separate the solids from the liquid.

The Structure of Filter Press

Basic Information

| Model | Filter Area (m22) | Filter plate size (mm) | Filter chamber volume (L) | Filter plate number (pcs) | Filtering pressure (Mpa) | Weight (kg) | Dimension(L×W×H) (mm) |

| XMY4/450-30U | 4 | 450×450 | 60 | 9 | 0.6 | 860 | 1950×700×900 |

| XMY6/450-30U | 6 | 450×450 | 91 | 14 | 0.6 | 910 | 2200×700×900 |

| XMY8/450-30U | 8 | 450×450 | 121 | 19 | 0.6 | 960 | 2450×700×900 |

| XMY10/450-30U | 10 | 450×450 | 151 | 24 | 0.6 | 1010 | 2700×700×900 |

| XMY12/450-30U | 12 | 450×450 | 182 | 29 | 0.6 | 1060 | 2950×700×900 |

| XMY15/450-30U | 15 | 450×450 | 225 | 36 | 0.6 | 1130 | 3300×700×900 |

| XMY16/450-30U | 16 | 450×450 | 243 | 39 | 0.6 | 1160 | 3450×700×900 |

| XMY15/630-30U | 15 | 630×630 | 226 | 18 | 0.6 | 1725 | 2640×900×1100 |

| XMY20/630-30U | 20 | 630×630 | 297 | 24 | 0.6 | 1993 | 3940×900×1100 |

| XMY30/630-30U | 30 | 630×630 | 452 | 37 | 0.6 | 2360 | 3590×900×1100 |

| XMY40/630-30U | 40 | 630×630 | 595 | 49 | 0.6 | 2788 | 4300×900×1100 |

| XMY30/870-30U | 30 | 870×870 | 460 | 23 | 0.6 | 2580 | 3180×1200×1300 |

| XMY40/870-30U | 40 | 870×870 | 595 | 30 | 0.6 | 2925 | 3570×1200×1300 |

| XMY50/870-30U | 50 | 870×870 | 748 | 38 | 0.6 | 3318 | 4110×1200×1300 |

| XMY60/870-30U | 60 | 870×870 | 902 | 46 | 0.6 | 3712 | 4550×1200×1300 |

| XMY70/870-30U | 70 | 870×870 | 1056 | 54 | 0.6 | 4106 | 4990×1200×1300 |

| XMY80/870-30U | 80 | 870×870 | 1210 | 62 | 0.6 | 4561 | 5430×1200×1300 |

| XMY50/1000-30U | 50 | 1000×1000 | 752 | 28 | 0.6 | 4072 | 4040×1500×1400 |

| XMY60/1000-30U | 60 | 1000×1000 | 914 | 34 | 0.6 | 4468 | 4460×1500×1400 |

| XMY70/1000-30U | 70 | 1000×1000 | 1063 | 40 | 0.6 | 4863 | 4760×1500×1400 |

| XMY80/1000-30U | 80 | 1000×1000 | 1219 | 46 | 0.6 | 5259 | 5120×1500×1400 |

| XMY100/1000-30U | 100 | 1000×1000 | 1505 | 57 | 0.6 | 5985 | 5800×1500×1400 |

| XMY120/1000-30U | 120 | 1000×1000 | 1816 | 69 | 0.6 | 6776 | 6500×1500×1400 |

| XMY100/1250-30U | 100 | 1250×1250 | 1479 | 36 | 0.6 | 6728 | 5020×1880×1600 |

| XMY120/1250-30U | 120 | 1250×1250 | 1777 | 43 | 0.6 | 7512 | 5740×1770×1600 |

| XMY140/1250-30U | 140 | 1250×1250 | 2094 | 51 | 0.6 | 8641 | 5990×1770×1600 |

| XMY160/1250-30U | 160 | 1250×1250 | 2381 | 58 | 0.6 | 8205 | 6450×1770×1600 |

| XMY180/1250-30U | 180 | 1250×1250 | 2669 | 65 | 0.6 | 10044 | 6905×1770×1600 |

| XMY200/1250-30U | 200 | 1250×1250 | 2965 | 72 | 0.6 | 10851 | 7360×1770×1600 |

| XMY220/1250-30U | 220 | 1250×1250 | 3285 | 80 | 0.6 | 11765 | 7880×1770×1600 |

| XMY250/1250-30U | 250 | 1250×1250 | 3737 | 91 | 0.6 | 12834 | 8600×1770×1600 |

| XMY200/1500-30U | 200 | 1500×1500 | 3025 | 49 | 0.6 | 19530 | 6400×2200×1900 |

| XMY250/1500-30U | 250 | 1500×1500 | 3739 | 61 | 0.6 | 22478 | 7225×2200×1900 |

| XMY300/1500-30U | 300 | 1500×1500 | 4413 | 74 | 0.6 | 25526 | 8130×2200×1900 |

| XMY350/1500-30U | 350 | 1500×1500 | 5210 | 86 | 0.6 | 28720 | 8570×2200×1900 |

| XMY400/1500-30U | 400 | 1500×1500 | 6007 | 99 | 0.6 | 32074 | 9880×2200×1900 |

| XMY450/1500-30U | 450 | 1500×1500 | 6743 | 111 | 0.6 | 35086 | 10820×2200×1900 |

| XMY500/1500-30U | 500 | 1500×1500 | 7478 | 123 | 0.6 | 38106 | 11560×2200×1900 |

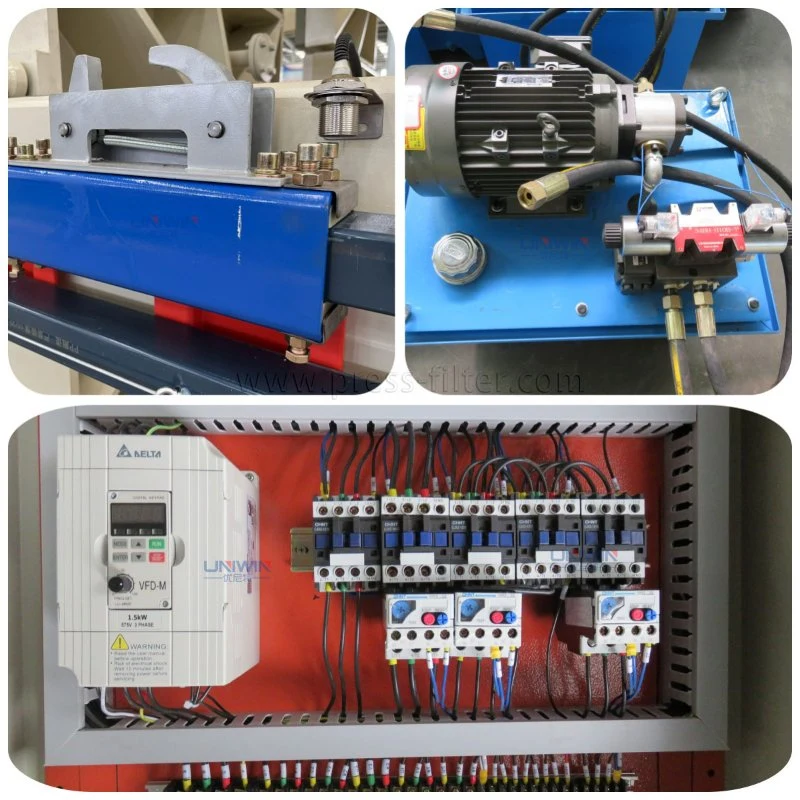

The Components of Filter Press

The filter press is mainly composed of frame, filter chamber, filter cloth, filter press plate and other components. When working, the water-containing liquid is fed into the filter chamber. Under the action of pressure, the liquid seeps out through the filter cloth, and the solid matter stays on the filter cloth to form a filter cake layer. After filtering, the filter cake can be removed for further processing.

Working Principle of Filter Press

The working principle of the filter press is mainly to use the pressure difference to separate the solid particles suspended in the water. Specifically, the suspended liquid to be treated is added to the filter chamber of the filter press, and then pressurized by compressed air or water pumps to increase the pressure in the filter chamber. When the pressure reaches a certain value, the solid particles in the suspended liquid will be intercepted by the filter medium (such as filter cloth, filter paper, etc.) and become solid substances, while the liquid will flow out through the filter medium and become filtrate. Finally, the process of solid-liquid separation can be completed by opening the drain door or turning over the filter press to remove the solid matter.

Working Process

Application

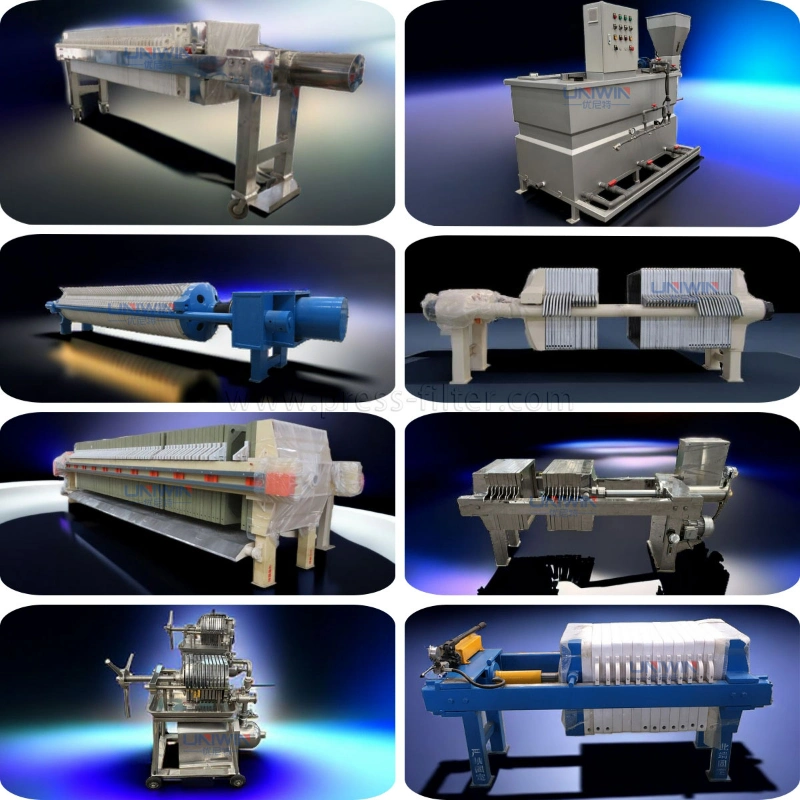

Hot Products

Factory Display

Customer Visiting