Basic Info.

Model NO.

1530

Cooling System

Water Cooling

Technical Class

Pulse Laser

Applicable Material

Metal

Structure Type

Table

Laser Classification

Gaseous Laser

Laser Technology

Laser Flame Cutting

Fiber Laser

2000W Raycus

Optional Power

500W 1000W 1500W 2000W

Machine Name

Metal Laser Cutting Machine

Machinery

Heavy Duty 2000W CNC Laser Cutter

Motor and Driver

Japan Yaskawa Servo Motor

Machinery Name

CNC Stainless Sheet Metal Fiber Laser Cutting Mach

Laser Head

Raytools Ipg Max

Metal Sheet Cutter

Fiber Laser Cutter Metal Sheet

Cooling Mode

Water Cooler

Gas

Oxygen or Nitrogen

Material

Carbon Steel Stailness Steel

Software

Cyput Software

Working Area

1500mmx3000mm or Customized

Metal Cutting Machine

Thailand Fiber Laser Cutter

Fiber Laser Cutter

Metal Laser Cutting Machine 1530

Transport Package

Wooden Case

Specification

1530

Trademark

ALLWIN

Origin

China

HS Code

8456100090

Packaging & Delivery

Package Size

480.00cm * 220.00cm * 190.00cm

Package Gross Weight

1900.000kg

Product Description

Features for 2000W 3000W LASER CUTTER CNC Sheet Metal Fiber Laser Cutting Machine for Sale

Features for 2000W 3000W LASER CUTTER CNC Sheet Metal Fiber Laser Cutting Machine for Sale 1.Low cost,laser power consumption only 0.5-1.5kw per hour.

2.China best quality laser source,high performance,stability and service lifespan over 100,000hours,free of maintenance.High speed ,high efficiency,thin plate cutting can be over 10 meters per minute.

3.Automatic height sensor on laser head for uneven pieces.

4.Imported ball screw and linear guide rail driving system.

5.Easy and efficient CNC software for fast programming.

| No. | machine model:ALLWIN-1530-2000W | ||||

| 1 | max working area | 1500mmx3000mm | |||

| 2 | Packing dimension | 2200mmx3700mmx1700mm | |||

| 3 | Laser source | 2000W RAYCUS fiber laser | |||

| 4 | laser head | Swiss RAYTOOLS with auto focus | |||

| 5 | software | Professional FSCUT2000 with Cypcut software | |||

| 6 | motor and driver | Japanese YASKAWA servo motors 850W | |||

| 7 | Reducer | Japan SHIMPO reducer | |||

| 8 | Water chiller | S&A brand with Dual temperature,dual control | |||

| 9 | Rack and pinion | Taiwan brand T-WIN rack and pinion | |||

| 10 | Guild rails | HIWIN GUILDER RAIL | |||

| 11 | Exhaust fan | Blower Exhaust fan | |||

| 12 | motor and driver | Japanese YASKAWA servo motors 850W | |||

| 13 | Air compressor | YES | |||

| 14 | voltage stabilizer | YES | |||

| 15 | Accessories included | 1 SET RAYCUS FIBER LASER SOURCE 2000W | |||

| 1 SET RAYTOOLS LASER HEAD(AUTOMATIC FOCUS) | |||||

| 1 SET WATER CHILLER | |||||

| CYPCUT SOFTWARE | |||||

| INDUSTRIAL COMPUTER | |||||

| FAN | |||||

| LASER PROTECTION GLASSES | |||||

| FIBER LASER CUTTING BED | |||||

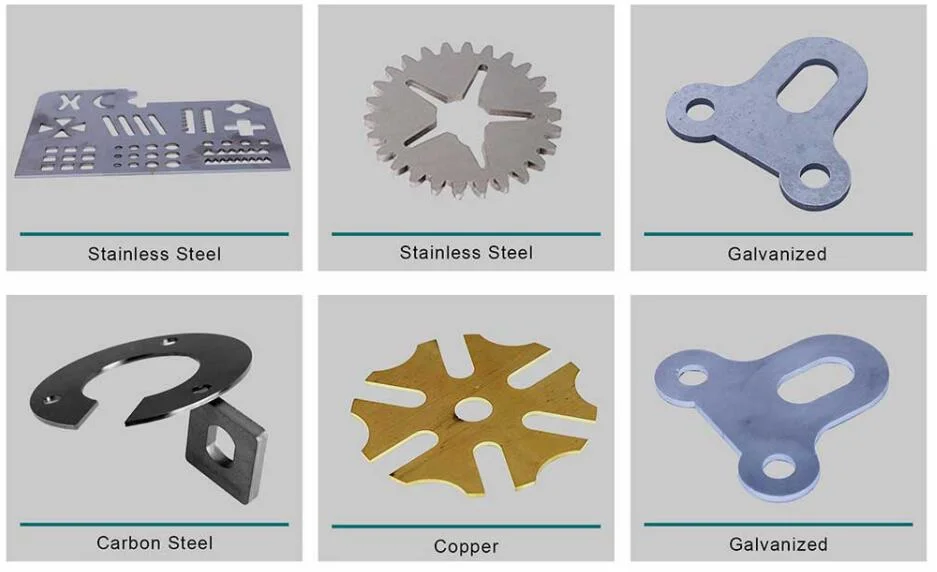

Cutting Samples:

Warranty for the machine

1. Two years quality guarantee for the main parts of the machine, excluding consuming parts, and the main parts shall be changed free of charge during the warranty time

2. Lifelong maintenance for the machine, and lifelong technical support from sophisticated English-speaking engineer team.

3. Free training course at our plant

4. We will provide the machine consuming parts with factory price when you need replacement.

5. 12 hours online service each day, free technical support.

Package and delivery the fiber laser cutting machine

1.Anti-collision package edge: All parts of the machine are covered with some soft materials, mainly the use of pearl wool .

2.Fumigation wooden box:Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3.Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

The outermost is a wooden box with a fixed template.

3.Wooden box at the bottom of a solid iron socket for easy handling.