Basic Info.

Model NO.

RG-BLS30

Specification

50kg, 125kg, 160kg

Trademark

Ruiguang

Origin

Weifang, China

Production Capacity

50000mt/Year

Product Description

Oxygen Bleaching Stabilizer RG-BLS30

Main ingredients: Multi-functional mixture of organic and inorganic substances

Physical and chemical indicators:

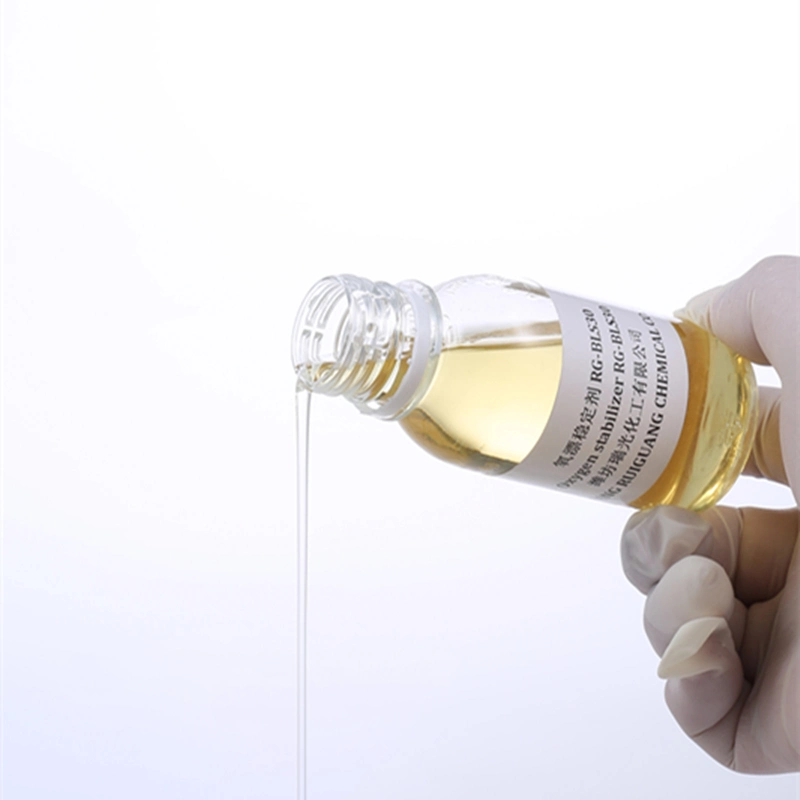

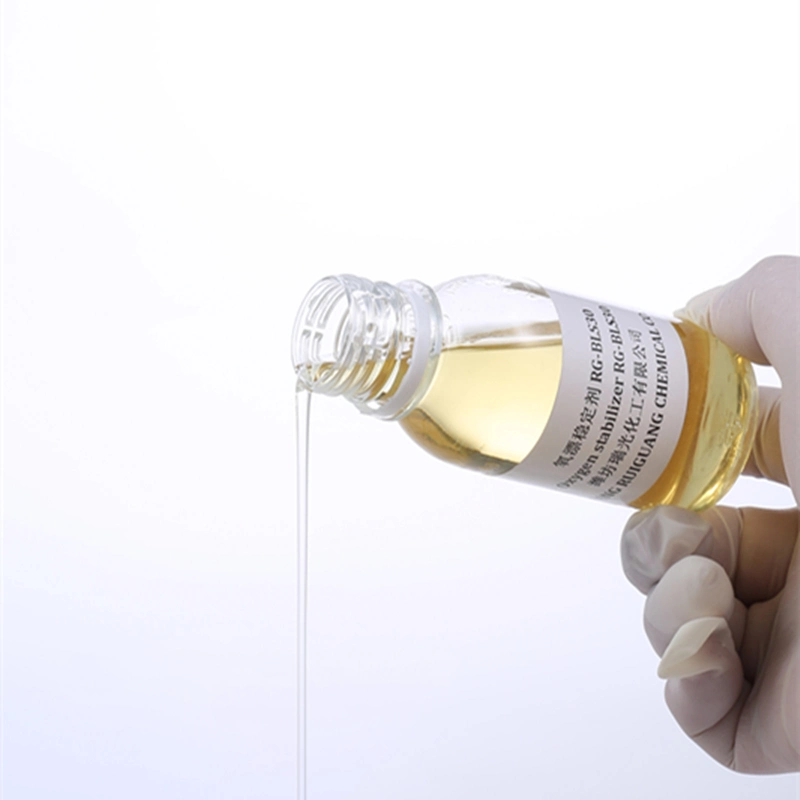

Appearance: Light yellow transparent liquid

Ionicity: Neak anionic/Nonionic

P H value: 3-5 (1% solution)

Solid content: 30±1%

Freezing point: -4 °C

Density: 1g/cm3 (at 20°C)

Performance characteristics and uses:

This product is a hydrogen peroxide bleaching stabilizer suitable for cellulose fiber and its synthetic fiber blended fabric. It can be used directly in bleaching without dilution.

The oxygen bleach stabilizer RG-BLS30 can stabilize peroxides such as hydrogen peroxide and sodium peroxide.

In an alkaline bleach bath, it prevents excessive decomposition of the peroxide and gives the fiber the best protection. During the bleaching process, its dispersion prevents the redeposition of impurities in the cotton and promotes the removal of impurities during the cleaning process.

Instructions:

Solution preparation:

Although it is not necessary to add any special order to the bleach solution, the following method is safer:

1. Add about half of the water first.

2. Add stabilizer RG-BLS30

3, caustic soda

4, wetting agent / detergent / refining agent

5, hydrogen peroxide

6, then add water to a certain volume

Reference formula:

Bleaching in a cheese dyeing machine:

27.5% hydrogen peroxide 2.6-7.6 g / liter

Caustic soda 10-15 g / l

RG-BLS30 0.3-0.7 g / l

Refining agent 2-4 g / liter

Bath ratio: 1:10, 90-100 ° C, 60-90 minutes or 110 ° C, 30-40 minutes

Bleaching in a rope dyeing machine:

27.5% hydrogen peroxide 2.6-5.1 g / liter

Caustic soda 10-22 g / l

RG-BLS30 0.15-0.35 g / l

Refining agent 4-6 g / l

Bath ratio: 1:15:1:30, 85-95 ° C, 1-2 hours

Bleaching in jet dyeing machines:

27.5% hydrogen peroxide 5.1-7.6 g / liter

Caustic soda 10-20 g / l

RG-BLS30 0.3-1 g / l

Additive 0.3-0.5 g / l

Bath ratio: 1:7-1:10, 90-100 ° C, 30-60 minutes

The specific process should be adjusted as appropriate according to the test.

Packing and storage:

This product is packed in 25KG, 50KG, 125KG plastic drums.

This product is non-dangerous, and should be protected from sun, high temperature and freezing during transportation and storage. The shelf life is one year at a temperature of 4 ° C to 20 ° C.

Main ingredients: Multi-functional mixture of organic and inorganic substances

Physical and chemical indicators:

Appearance: Light yellow transparent liquid

Ionicity: Neak anionic/Nonionic

P H value: 3-5 (1% solution)

Solid content: 30±1%

Freezing point: -4 °C

Density: 1g/cm3 (at 20°C)

Performance characteristics and uses:

This product is a hydrogen peroxide bleaching stabilizer suitable for cellulose fiber and its synthetic fiber blended fabric. It can be used directly in bleaching without dilution.

The oxygen bleach stabilizer RG-BLS30 can stabilize peroxides such as hydrogen peroxide and sodium peroxide.

In an alkaline bleach bath, it prevents excessive decomposition of the peroxide and gives the fiber the best protection. During the bleaching process, its dispersion prevents the redeposition of impurities in the cotton and promotes the removal of impurities during the cleaning process.

Instructions:

Solution preparation:

Although it is not necessary to add any special order to the bleach solution, the following method is safer:

1. Add about half of the water first.

2. Add stabilizer RG-BLS30

3, caustic soda

4, wetting agent / detergent / refining agent

5, hydrogen peroxide

6, then add water to a certain volume

Reference formula:

Bleaching in a cheese dyeing machine:

27.5% hydrogen peroxide 2.6-7.6 g / liter

Caustic soda 10-15 g / l

RG-BLS30 0.3-0.7 g / l

Refining agent 2-4 g / liter

Bath ratio: 1:10, 90-100 ° C, 60-90 minutes or 110 ° C, 30-40 minutes

Bleaching in a rope dyeing machine:

27.5% hydrogen peroxide 2.6-5.1 g / liter

Caustic soda 10-22 g / l

RG-BLS30 0.15-0.35 g / l

Refining agent 4-6 g / l

Bath ratio: 1:15:1:30, 85-95 ° C, 1-2 hours

Bleaching in jet dyeing machines:

27.5% hydrogen peroxide 5.1-7.6 g / liter

Caustic soda 10-20 g / l

RG-BLS30 0.3-1 g / l

Additive 0.3-0.5 g / l

Bath ratio: 1:7-1:10, 90-100 ° C, 30-60 minutes

The specific process should be adjusted as appropriate according to the test.

Packing and storage:

This product is packed in 25KG, 50KG, 125KG plastic drums.

This product is non-dangerous, and should be protected from sun, high temperature and freezing during transportation and storage. The shelf life is one year at a temperature of 4 ° C to 20 ° C.