Basic Info.

Model NO.

RG-BLS30

Ionicity

Weak Anionic/Nonionic

pH

3.0-5.0

Freezing Point

-4 Degree

Density

1g/cm3

Transport Package

Plastic Drum

Specification

25kg, 50kg, 160kg

Trademark

RG

Origin

Weifang, China

Production Capacity

50000mt/Year

Product Description

Oxygen Bleaching Stabilizer RG-BLS30

Physical and chemical index:

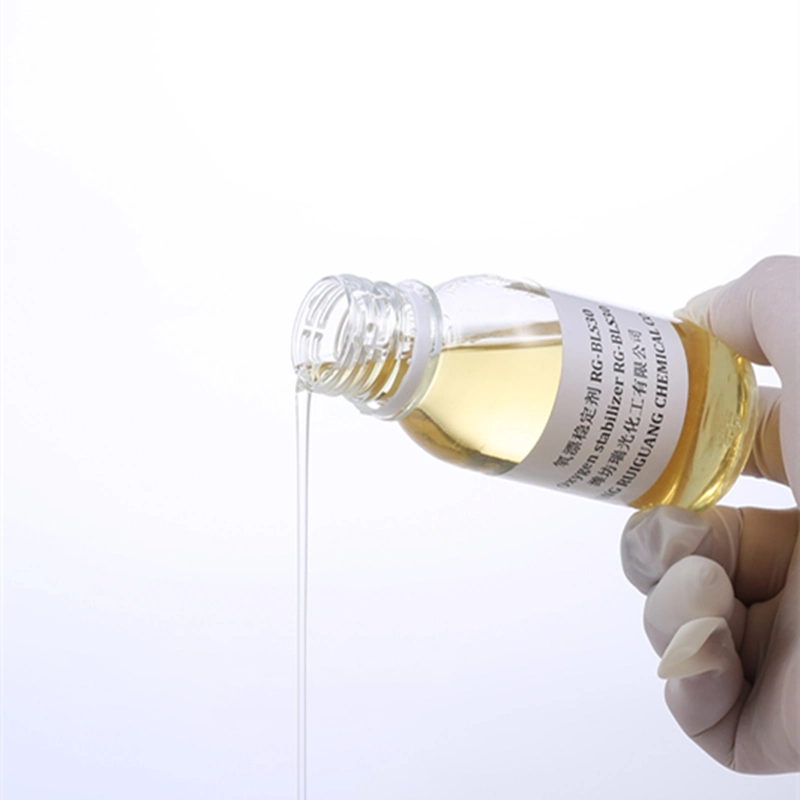

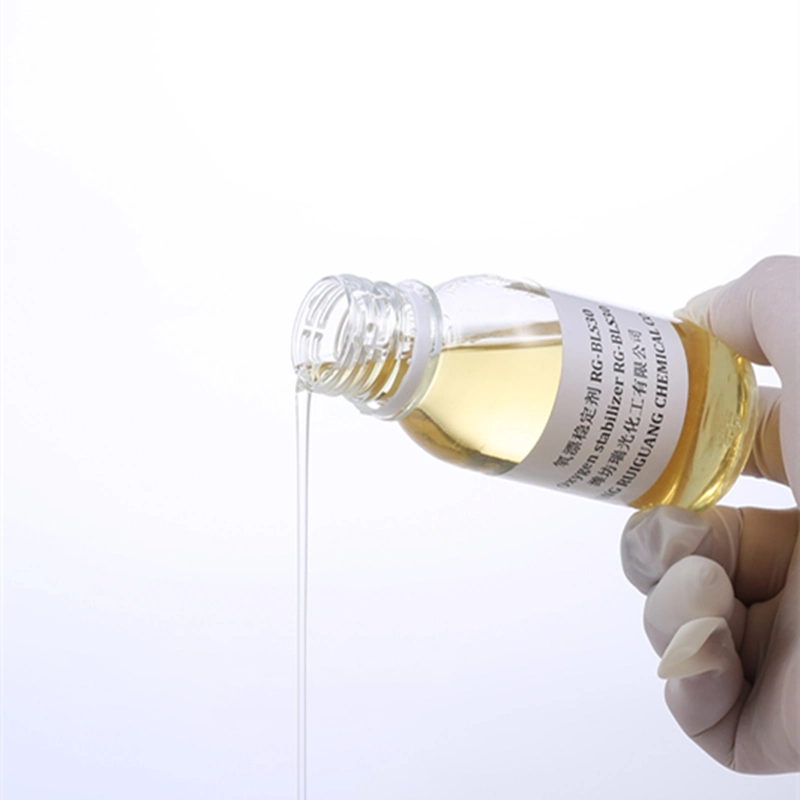

Appearance: Light yellow transparent liquid

Solid Content: 30±1%

Ionicity: Weak anionic/Nonionic

PH: 3.0-5.0

Freezing point: -4ºC

Density: 1g/cm3 (20ºC)

Performance feature:

Apply to stabilize cellulose fiber and its blended fabrics bleaching process which bleached with H2O2 or Na2O2. It could prevent peroxide decomposing too fast and protect fiber. It also could prevent impurities sediment and promote them removing.

Usage and dosage:

Please add the chemicals in this sequence to bleaching liquid:

1, Add 50% water;

2, Add RG-BLS30;

3, Add NAOH;

4, Wetting agent/detergent/scouring agent;

5, Add H2O2;

6, Add water to certain volume

Recommended formula:

For cheese dyeing machine bleaching:

27.5% H2O2 2.6-2.7 g/L

NAOH 10-15 g/L

RG-BLS30 0.3-0.7 g/L

Scouring agent 2-4 g/L

Bath Ratio: 1:10, 90-100ºC, 60-90mins or 110ºC,30-40mins

Rope dyeing machine bleaching:

27.5% H2O2 2.6-5.1 g/L

NAOH 10-22 g/L

RG-BLS30 0.15-0.35 g/L

Scouring agent 4-6 g/L

Bath Ratio: 1:15-1:30, 85-95ºC, 1-2 hours

Jet dyeing machine bleaching

27.5% H2O2 5.1-7.6 g/L

NAOH 10-20 g/L

RG-BLS30 0.3-1.0 g/L

Scouring agent 0.3-0.5 g/L

Bath Ratio: 1:7-1:10, 90-100ºC, 30-40mins

Packaging and Storage:

Package: 25kg, 50kg, 125kg or 160kg plastic drum.

Prevent sunshine, high temperature and freeze. One year shelf life in 4-20ºC

Physical and chemical index:

Appearance: Light yellow transparent liquid

Solid Content: 30±1%

Ionicity: Weak anionic/Nonionic

PH: 3.0-5.0

Freezing point: -4ºC

Density: 1g/cm3 (20ºC)

Performance feature:

Apply to stabilize cellulose fiber and its blended fabrics bleaching process which bleached with H2O2 or Na2O2. It could prevent peroxide decomposing too fast and protect fiber. It also could prevent impurities sediment and promote them removing.

Usage and dosage:

Please add the chemicals in this sequence to bleaching liquid:

1, Add 50% water;

2, Add RG-BLS30;

3, Add NAOH;

4, Wetting agent/detergent/scouring agent;

5, Add H2O2;

6, Add water to certain volume

Recommended formula:

For cheese dyeing machine bleaching:

27.5% H2O2 2.6-2.7 g/L

NAOH 10-15 g/L

RG-BLS30 0.3-0.7 g/L

Scouring agent 2-4 g/L

Bath Ratio: 1:10, 90-100ºC, 60-90mins or 110ºC,30-40mins

Rope dyeing machine bleaching:

27.5% H2O2 2.6-5.1 g/L

NAOH 10-22 g/L

RG-BLS30 0.15-0.35 g/L

Scouring agent 4-6 g/L

Bath Ratio: 1:15-1:30, 85-95ºC, 1-2 hours

Jet dyeing machine bleaching

27.5% H2O2 5.1-7.6 g/L

NAOH 10-20 g/L

RG-BLS30 0.3-1.0 g/L

Scouring agent 0.3-0.5 g/L

Bath Ratio: 1:7-1:10, 90-100ºC, 30-40mins

Packaging and Storage:

Package: 25kg, 50kg, 125kg or 160kg plastic drum.

Prevent sunshine, high temperature and freeze. One year shelf life in 4-20ºC