- Overview

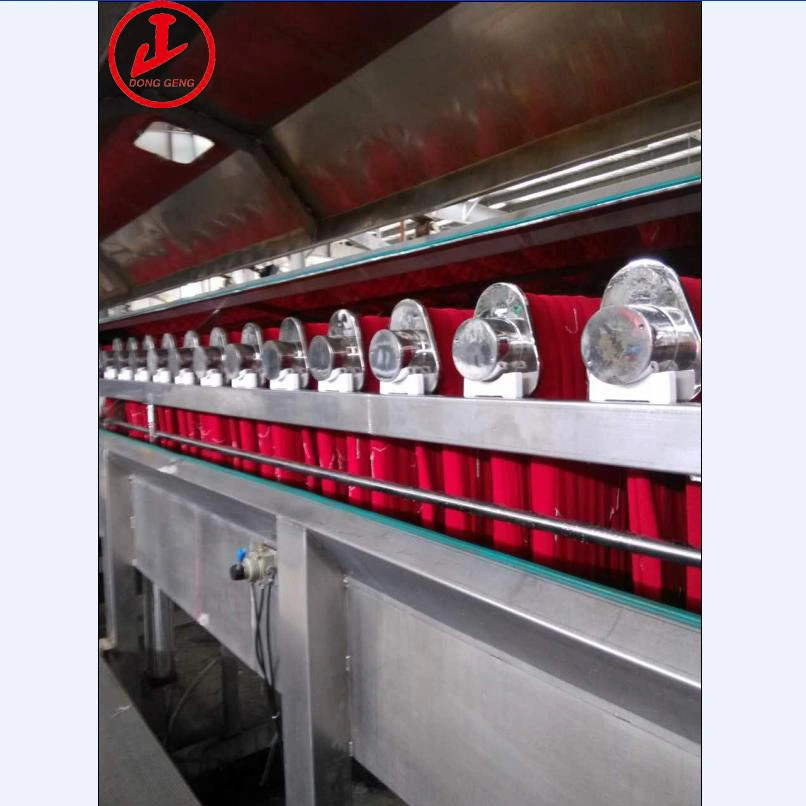

- Product Description

- Dyeing principle

- Packing & Delivery

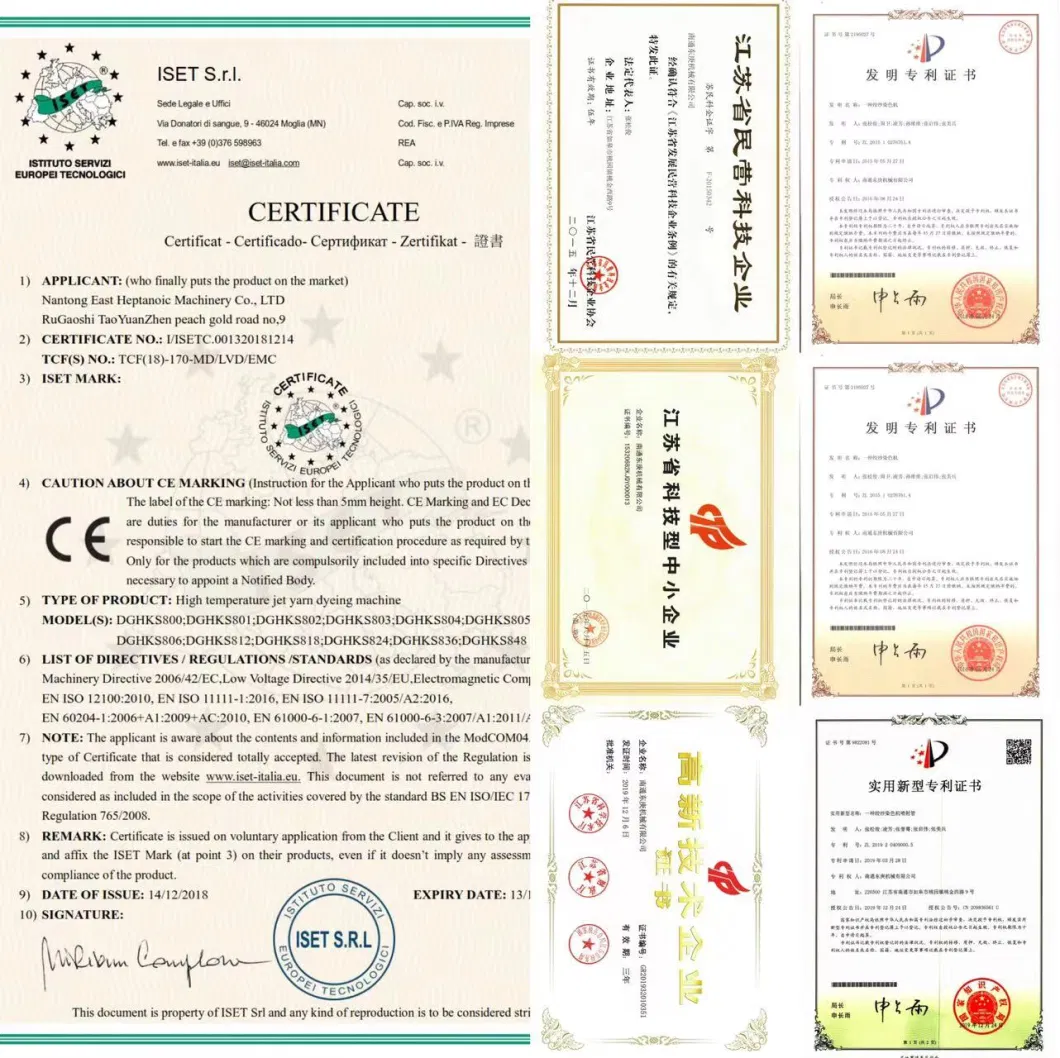

- Company Profile

- Exhibition

- Contact Us

- Recommend Products

Basic Info.

Model NO.

DGHKS-Warp beam

Warranty

1 Year

Customized

Customized

Condition

New

After-sales Service

24 Hours Technical Support by Email, Call, Video

Garment Polyester

Garment Polyester

Width

Cheese Dryer

Purpose

Fabric Jigger Machine

Purpose1

High Temperature High Pressure

Purpose2

Warp Beam Dyeing Machine

Purpose3

Real Silk

Purpose4

Triangular Shaped Shiny Silk

Purpose5

Nylon Spun

Purpose6

Nylon 66

Transport Package

Standard Package or Nude Package Customized

Specification

2900*5000*2600

Trademark

DONGGENG

Origin

China

HS Code

8451400000

Production Capacity

20

Product Description

| DGHKS high temperature multi-purpose beam dyeing machine is mainly used for economical dyeing of various fabrics. Suitable for open-width fabrics with out tension Dyeing, bleaching and pre-treatment are carried out in the state. For sensitive fabrics, woven fabrics, knitted fabrics,non-woven fabrics, easily deformed,Easy hemming open width fabrics, dyeing options available. Main Feature 1. Wide range of application; suitable for nylon, pagoda silk, rich silk, real silk, shell light silk plain fabric, polyester fabric,Blue Card Stretch, Oxford, Computer Embroidered Lace and Tricot. 2. Reasonable small sample sampling device, simple setting and flexible sampling. 3. The adjustable looper structure ensures the adjustment of various width fabrics. 4. Special computer for dyeing machine, easy to control, temperature rise and fall, water intake,drainage, washing, feeding, internal and external pressure during the dyeing process .The difference setting can be fully automatic operation, reducing the negligence of human operation. 5. The diameter of the dyeing vat can reach Φ400mm to Φ1660mm, the width of the fabric and the length of the cylinder are designed according to the needs of customers. Detail machine pictures, all photoes are for 100% real shooting ! For more pictures, video and details, please email me! |

|

| The dyeing of the warp beam dyeing machine is mainly to let the dye liquor under the suction of the motor pump, and finally dye the fabric during the circulation process of the dye vat and the feeding barrel. The warp beam dyeing machine has main and auxiliary dye liquor circulation processes. The so-called "main circulation" process is: after the prepared dye liquor is heated by the heat exchanger, it is ejected through the dye liquor jet under the action of the main pump, and the dye liquor will completely permeate through the dye liquor under the action of the pressure difference. through the fabric before entering the heat exchanger for the next cycle. The so-called "auxiliary circulation" means that the volume of the dye liquor in the dye vat expands during the heating process, the dye liquor enters the material barrel, and then enters the injection port of the dye liquor under the action of the feeding pump to start the next main cycle. The cycle is repeated until the time specified by the process is completed. Due to the different structural characteristics of filament fabrics, non-woven fabrics and silk fabrics, long fiber fabrics and non-woven fabrics will produce a certain amount of entanglement during the dyeing process. For silk fabrics, almost no fibers are scattered and entangled from the surface of the fabric during the dyeing process, so the structures of these two types of warp beam dyeing machines are also different. |

|

| Nantong Donggeng Machinery Co., Ltd. is located in taoyuan industrial zone, rugao software park, the longevity town, located in nantong city, north of the Yangtze river in the Yangtze river delta.The company specializes in the manufacture and development of textile printing and dyeing machinery equipment, is a private scientific and technological enterprise in jiangsu province and a high-tech enterprise in jiangsu province, enjoying a good reputation among peers in the industry. Company has dyeing and mechanical industry more than technical staff, strong technical force, excellent processing equipment, advanced product technology, detection means complete, stable quality, reliable performance, products in addition to satisfy the masses of customers at home and abroad, also exported to other countries and regions of the world, with excellent quality, high-quality perfect after-sales service, wins the general customers trust and praise. Specialized in high temperature, room temperature yarn dyeing machine development and manufacturing enterprises.Engaged in this field has more than 30 years of history, the main products are series of high temperature and high pressure DGHKS jet Hank dyeing machine, DGCKS series high temperature and high pressure cheese dyeing machine, DGAKS series of atmospheric pressure jet Hank dyeing machine, the bobbin DGRDKS high-speed dryer, DGSKS high temperature and high pressure vacuumalready set machine DGTYD tunnel Hank dryers and other products, is the domestic and foreign dyeing manufacturers the ideal choice. The company is willing to first-class products and excellent after-sales service for new and old customers at home and abroad. |

|  |

| High Temperature Dyeing Machine for Loose Wool Fiber Production Line/Kier for Medical Cotton Bleaching | Top Quality China National Standard Batik Dyeing Machine Automatic Spray Yarn Dyeing Machine Normal Temperature Jet Dyeing Machine Yarn Develop |