Basic Info.

Model NO.

LT-S

Voltage

380V

Load Capacity

<500kg

Certification

CE, ISO9001: 2000

Warranty

1 Year

Customized

Customized

Condition

New

After-sales Service

Lifetime After-Sale Service

Transport Package

Standard Package

Specification

ID 1200MM, 1500MM, 1800MM

Trademark

unitex

Origin

China

HS Code

84519000

Production Capacity

500sets/Year

Product Description

1. Product names and descriptions

VACUUM CONDITIONING and STEAMING MACHINE HONST

Type LT-S Φ1600×3000S

Indirect heating system, reduce vessel's air pressure so as to reduce water's boiling point through evacuation to produces low temperature saturated steam. Saturated steam from low temperature to high temperature ensures yarn mellowing treatment.

2. Basic Machine Data

1). Capacity 500 Kg (Base on cotton yarn cones by pin trolley)

2). Tank model Diameter of tank: 1600mm Usable length: 3000mm

3). Outer dimensions L:6000mm, W:2100mm, H:2200mm.

4). Treatment temperature: 50ºC~110ºC(saturated steam)

5). Working pressure: -0.085~+0.05MPa

6). Heating method: steam heating.

7). Insulation layer: 70mm rock-wool with aluminum outer cover.

8). Door opening mode: automatic side opening door by oil pump with 0.75KW electric motor.

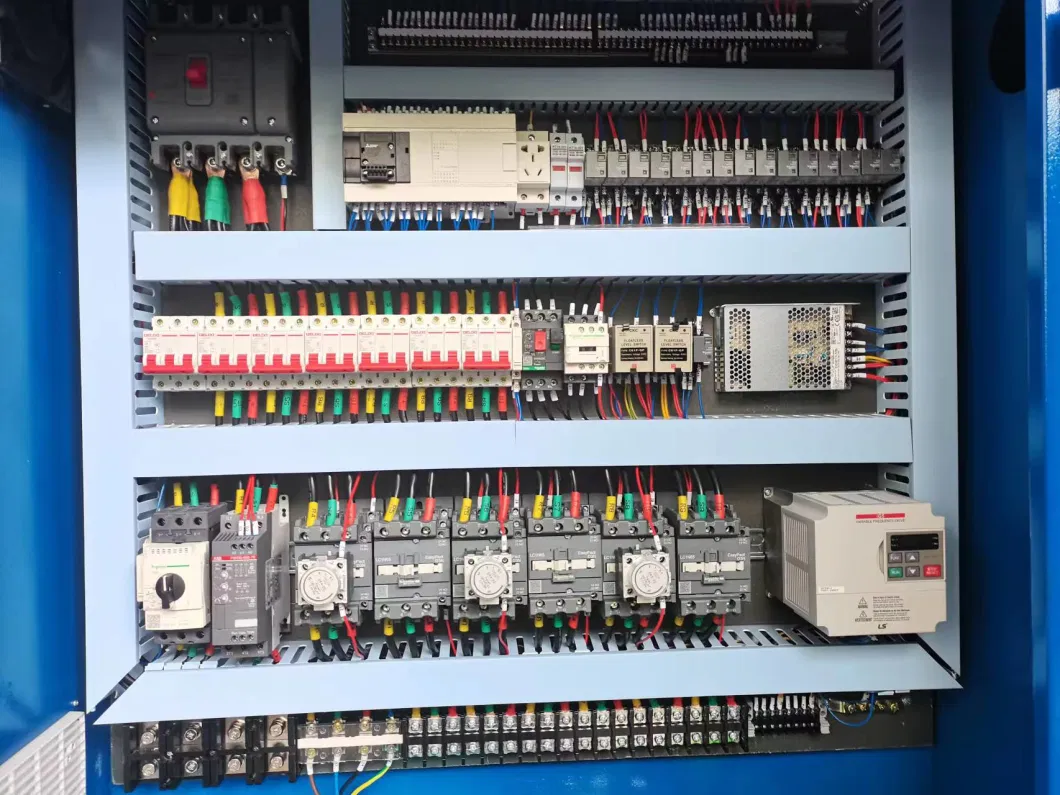

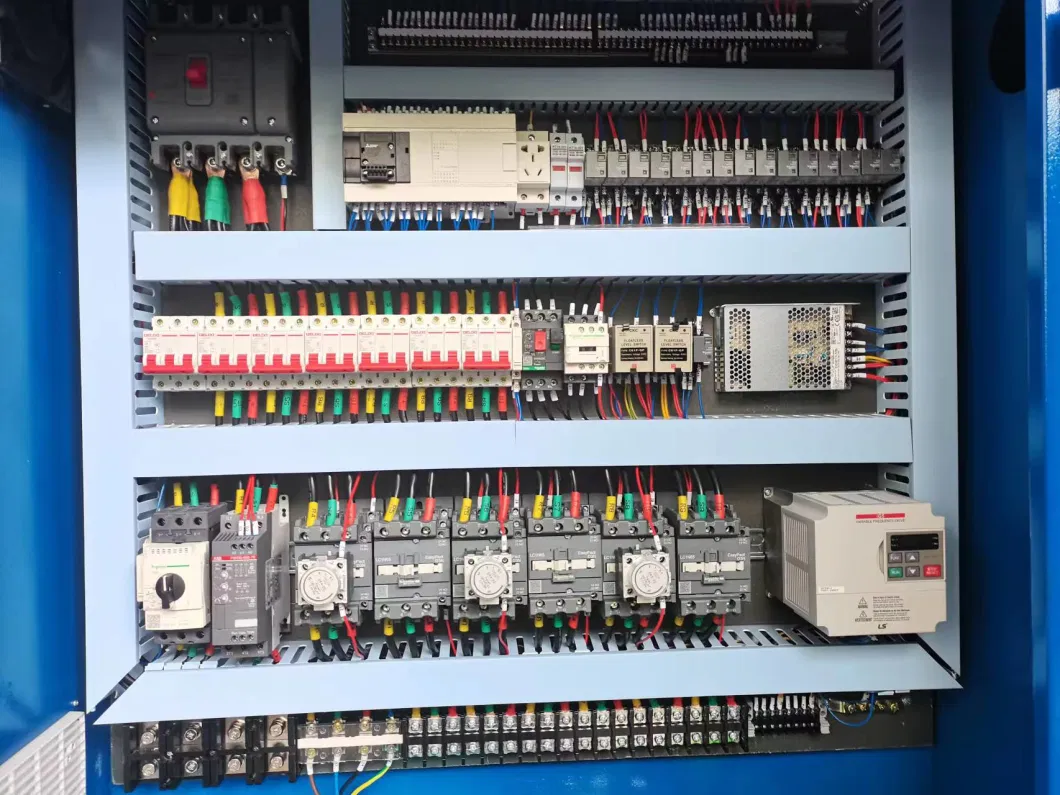

Electric cabinet of the controlling system:

VACUUM CONDITIONING and STEAMING MACHINE HONST

Type LT-S Φ1600×3000S

Indirect heating system, reduce vessel's air pressure so as to reduce water's boiling point through evacuation to produces low temperature saturated steam. Saturated steam from low temperature to high temperature ensures yarn mellowing treatment.

2. Basic Machine Data

1). Capacity 500 Kg (Base on cotton yarn cones by pin trolley)

2). Tank model Diameter of tank: 1600mm Usable length: 3000mm

3). Outer dimensions L:6000mm, W:2100mm, H:2200mm.

4). Treatment temperature: 50ºC~110ºC(saturated steam)

5). Working pressure: -0.085~+0.05MPa

6). Heating method: steam heating.

7). Insulation layer: 70mm rock-wool with aluminum outer cover.

8). Door opening mode: automatic side opening door by oil pump with 0.75KW electric motor.

Electric cabinet of the controlling system: