Basic Info.

Feature

Durable Stainless Steel Body

Transport Package

Wooden Cases with Iron Hoops

Specification

72kW

Trademark

Pindom

Origin

Guangdong, China

Product Description

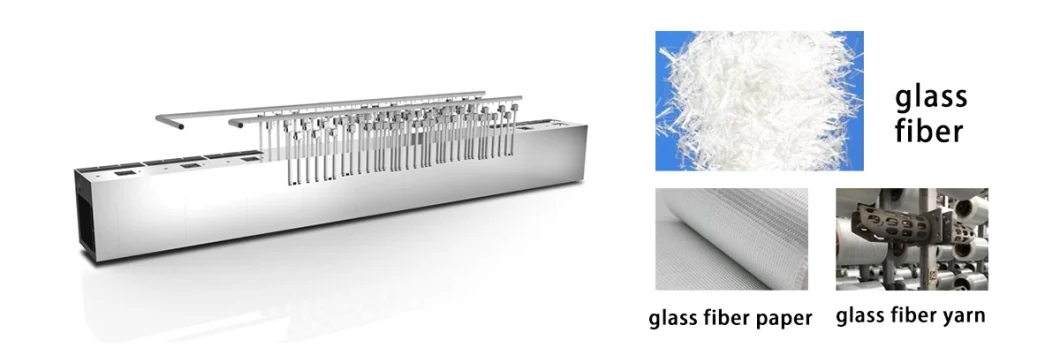

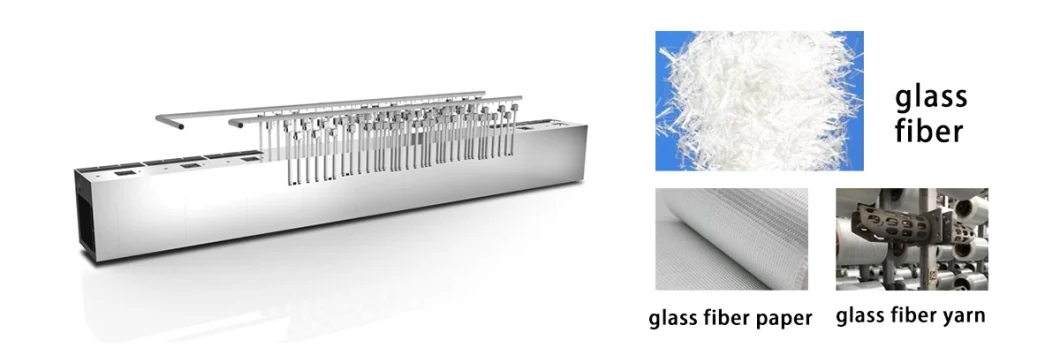

Commercial Industrial Drying Equipment PLC Fiberglass Microwave Drying Fiberglass Paper Machine

Glass fiber microwave dryer 1. The product has good quality of drying and shaping, no stretching and no bursting yarn.

Glass fiber microwave dryer 1. The product has good quality of drying and shaping, no stretching and no bursting yarn.

2. Easy to control, convenient and flexible operation, automatic control of heating time and drying temperature.

Glass Fiber Microwave Drying Machine Equipment Glass Fiber Microwave Drying Machine Equipment

Glass Fiber Microwave Drying Machine Equipment

1. Why should you buy from us instead of another supplier?

1. Why should you buy from us instead of another supplier?

We are a professional and innovative team. With independent research and development and production capacity, quality and service first, abide by the spirit of business and contract.

2. How can we guarantee the quality?

Our products are subject to strict testing at every stage from production, packaging to pre-shipment.

3. Payment

1. Terms of payment: telegraphic transfer, letter of credit, credit card, etc. Please contact us for details.

2. Please fill in the complete information, contact person, address, ZIP code and phone number when placing an order to ensure the smooth delivery of your goods.

4. Shipping

1. After confirming the payment, we will deliver the goods within 2~5 working days.

2. We will provide the best transportation company and transportation route for you to choose.

5. Quotation

1. Generally, the quotation will be completed within 1 working day.

2. For complex customized products or products requiring mold opening, we may need more time to calculate the cost and then give you a quotation.

6. After-sale service and warranty

1. The warranty period of our products is 3 months to 2 years. The warranty time start calculating upon customers receiving the goods.

2. We provide paid repair service for artificially damaged products and fragile accessories.

3. Any quality issues please feel free to contact us. We are dedicated to solve the problem for you.

7. The feedback

1. As your feedback is very important to our business development, we sincerely invite you to give the feedback.

2. We will deal with your feedback in time, and you can also keep in touch with our customer service and get the updated progress.

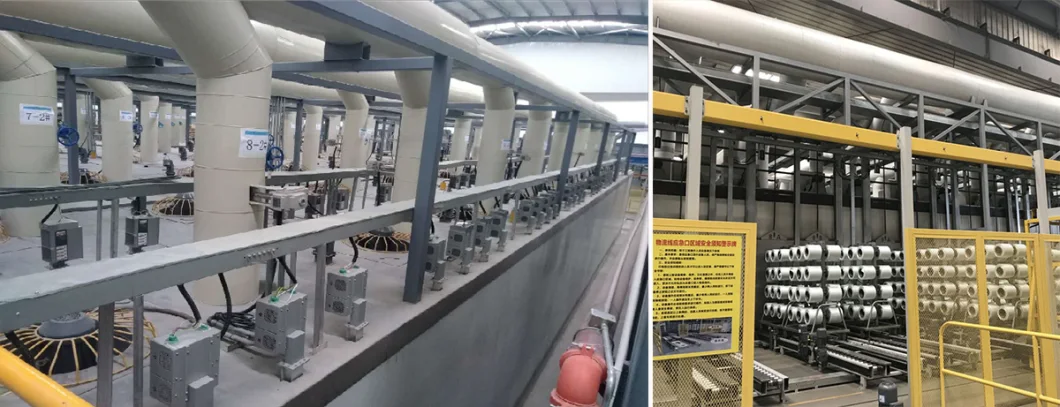

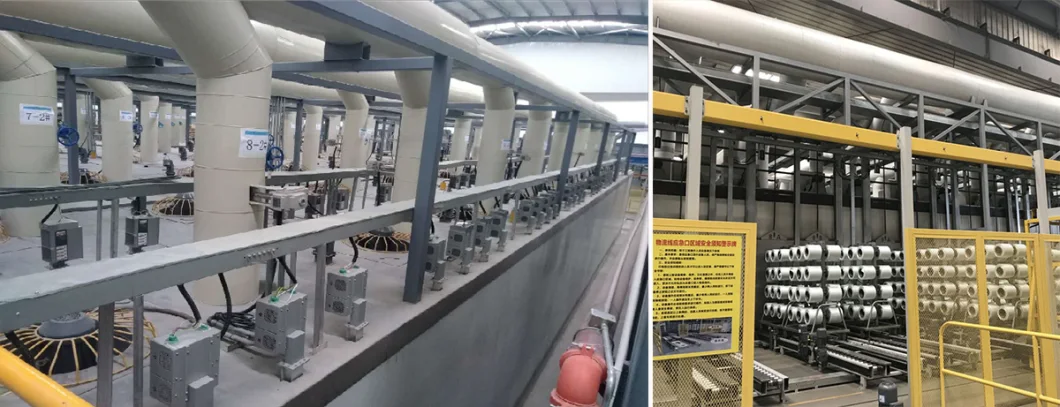

| Item | OEM ODM Stainless Steel PLC Glass Fiber Microwave Drying Machine |

| Microwave Power | 62kW |

| Power | 72kW |

| Voltage | 380V,50hz |

| Output | Drying time 8 hours,1 hour 12 car spindle |

| Control | PLC+ LIQUID crystal touch control, frequency conversion microwave power supply |

| Application | Glass fiber drying,Glass fiber yarn, all kinds of textile and special yarn |

| Material | Stainless steel,SUS304 |

| Size | 40m*5m*4m |

| N.W | 40T |

| Package | The industrial microwave custom equipment is packed in wooden cases with iron hoops. |

| Lead Time | 30-45 days |

| Load-bearing Capacity | As your requirement |

| OEM/ODM | Acceptable |

Glass fiber microwave dryer

Glass fiber microwave dryer 2. Easy to control, convenient and flexible operation, automatic control of heating time and drying temperature.

3. Save time, high output.

4. Each power supply and magnetron working state can be seen, high degree of automation.

5. Environmental protection and hygiene. No pollution, not to mention the "three wastes" problem

4. Each power supply and magnetron working state can be seen, high degree of automation.

5. Environmental protection and hygiene. No pollution, not to mention the "three wastes" problem

Glass Fiber Microwave Drying Machine Equipment

Glass fiber microwave dryer can dry all the remaining water in the glass fiber until the glass fiber is completely dried.Microwave dryer is the appropriate choice for glass fiber drying.

Glass Fiber Microwave Drying Machine Equipment

OEM/ODM Length, width, height can be based on Customer request to customize. The microwave drying equipment for glass fiber can be designed according to the size and shape of materials, the different requirements and characteristics of drying temperature, film forming time, hardness and moisture content. Glass Fiber Microwave Drying Machine Equipment

Glass Fiber Microwave Drying Machine Equipment

Glass Fiber Microwave Drying Machine Equipment

Glass Fiber Microwave Drying Machine Equipment

Glass Fiber Microwave Drying Machine Equipment

Glass Fiber Microwave Drying Machine Equipment

Advantages of microwave drying method:

Advantages of microwave drying method:

1. Heat quickly and evenly

Because of the microwave absorption medium has a strong penetration ability, heat directly to the energy of the whole material, instantaneous conversion into heat in the material inside, greatly shorten the heating time.

Because of the microwave absorption medium has a strong penetration ability, heat directly to the energy of the whole material, instantaneous conversion into heat in the material inside, greatly shorten the heating time.

Glass Fiber Microwave Drying Machine Equipment

2. Selectivity of heating

Microwave heating uses the principle of dielectric loss, which converts electromagnetic energy into heat energy through dielectric loss in the heating process. Only the material absorbing microwave can be heated by microwave. Water absorbs much more microwave energy than other substances because of its high dielectric loss.

Microwave heating uses the principle of dielectric loss, which converts electromagnetic energy into heat energy through dielectric loss in the heating process. Only the material absorbing microwave can be heated by microwave. Water absorbs much more microwave energy than other substances because of its high dielectric loss.

Glass Fiber Microwave Drying Machine Equipment

3. High thermal efficiency and energy saving

Microwave directly interacts with the material, there is no need to heat the air or heat a large area of equipment wall, and the heating chamber is made of metal closed cavity, which can not only improve the heat utilization rate, but also ensure the safety of operators. At the same time, the cavity reflects microwave, so that it does not leak out, can only be absorbed by the material.

Microwave directly interacts with the material, there is no need to heat the air or heat a large area of equipment wall, and the heating chamber is made of metal closed cavity, which can not only improve the heat utilization rate, but also ensure the safety of operators. At the same time, the cavity reflects microwave, so that it does not leak out, can only be absorbed by the material.

Glass Fiber Microwave Drying Machine Equipment

4. Sensitive response, easy to control, high product quality

In microwave drying, the surface temperature of the material is lower than the center, so the phenomenon of temperature overheating and crusting rarely appears on the surface of the material, which is conducive to the evaporation of water. Using wind heat or steam to heat the surface is beneficial to uniform heating of the body. The output of energy can be controlled by the power switch to improve product quality.

In microwave drying, the surface temperature of the material is lower than the center, so the phenomenon of temperature overheating and crusting rarely appears on the surface of the material, which is conducive to the evaporation of water. Using wind heat or steam to heat the surface is beneficial to uniform heating of the body. The output of energy can be controlled by the power switch to improve product quality.

Lead Time:30-45 days.

Lead Time:30-45 days.

Packaging Details:The industrial microwave custom equipment is packed in wooden cases with iron hoops.

Port:Shenzhen/Zhongshan/Guangzhou/Zhuhai,China.

1. Why should you buy from us instead of another supplier?

1. Why should you buy from us instead of another supplier? We are a professional and innovative team. With independent research and development and production capacity, quality and service first, abide by the spirit of business and contract.

2. How can we guarantee the quality?

Our products are subject to strict testing at every stage from production, packaging to pre-shipment.

3. Payment

1. Terms of payment: telegraphic transfer, letter of credit, credit card, etc. Please contact us for details.

2. Please fill in the complete information, contact person, address, ZIP code and phone number when placing an order to ensure the smooth delivery of your goods.

4. Shipping

1. After confirming the payment, we will deliver the goods within 2~5 working days.

2. We will provide the best transportation company and transportation route for you to choose.

5. Quotation

1. Generally, the quotation will be completed within 1 working day.

2. For complex customized products or products requiring mold opening, we may need more time to calculate the cost and then give you a quotation.

6. After-sale service and warranty

1. The warranty period of our products is 3 months to 2 years. The warranty time start calculating upon customers receiving the goods.

2. We provide paid repair service for artificially damaged products and fragile accessories.

3. Any quality issues please feel free to contact us. We are dedicated to solve the problem for you.

7. The feedback

1. As your feedback is very important to our business development, we sincerely invite you to give the feedback.

2. We will deal with your feedback in time, and you can also keep in touch with our customer service and get the updated progress.

Commercial Industrial Drying Equipment PLC Fiberglass Microwave Drying Fiberglass Paper Machine