- Overview

- Product Description

- Product Specification

- Product Advantages

- Technology conditions

- Storage

Basic Info.

Model NO.

GR-M111-4

Appearance

Liquid

Effect

Desizing and Polishing in One Bath

Quality

High Concentrated

Active

100%

Specifications

Standard

Transport Package

30kg/ Drum

Specification

30KG/Drum

Trademark

GR

Origin

China

HS Code

35079090

Production Capacity

500 Ton/Month

Product Description

Scouring Polishing One Bath Enzyme GR-M111-4

Appearance: tawny liquid

Scouring+Polishing one bath enzyme GR-M111-4 is a compound enzyme containing a variety of pectinase components and xylanase, cellulase, lipase and other enzymes. It is an ideal bio refining enzyme, which is widely used in various pre-treatment processes of cotton, interwoven or blended fabrics and yarns. The process when used in hemp degumming and textile refining can remove the pectin impurities of cotton fibers and other co-biological impurities.

Components: complex product of various enzymes based on alkaline pectinase

Appearance: tawny liquid

Function temperature range: 40-55ºC

function PH value range: 6.0-7.0

Merge enzyme desizing process and can be performed simultaneously with bio polishing process, also can bath with dyeing. Shorten processing time, improve production efficiency; the fabric weightlessness reduced, defect rate decreased;

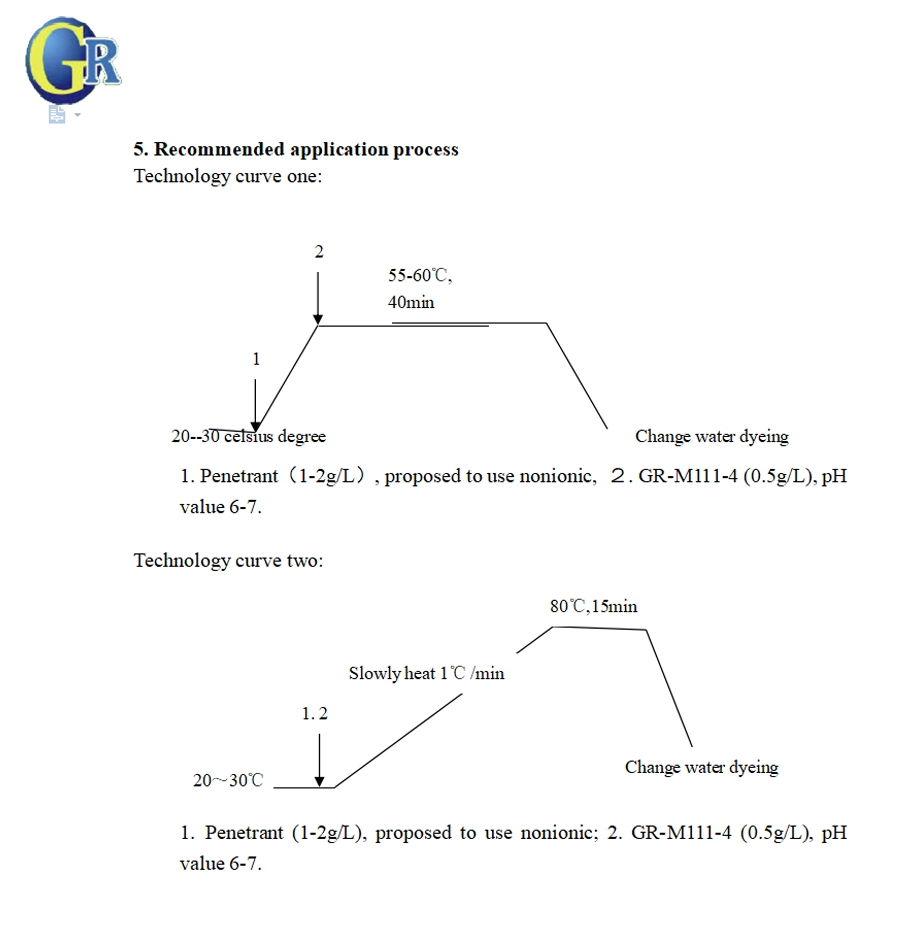

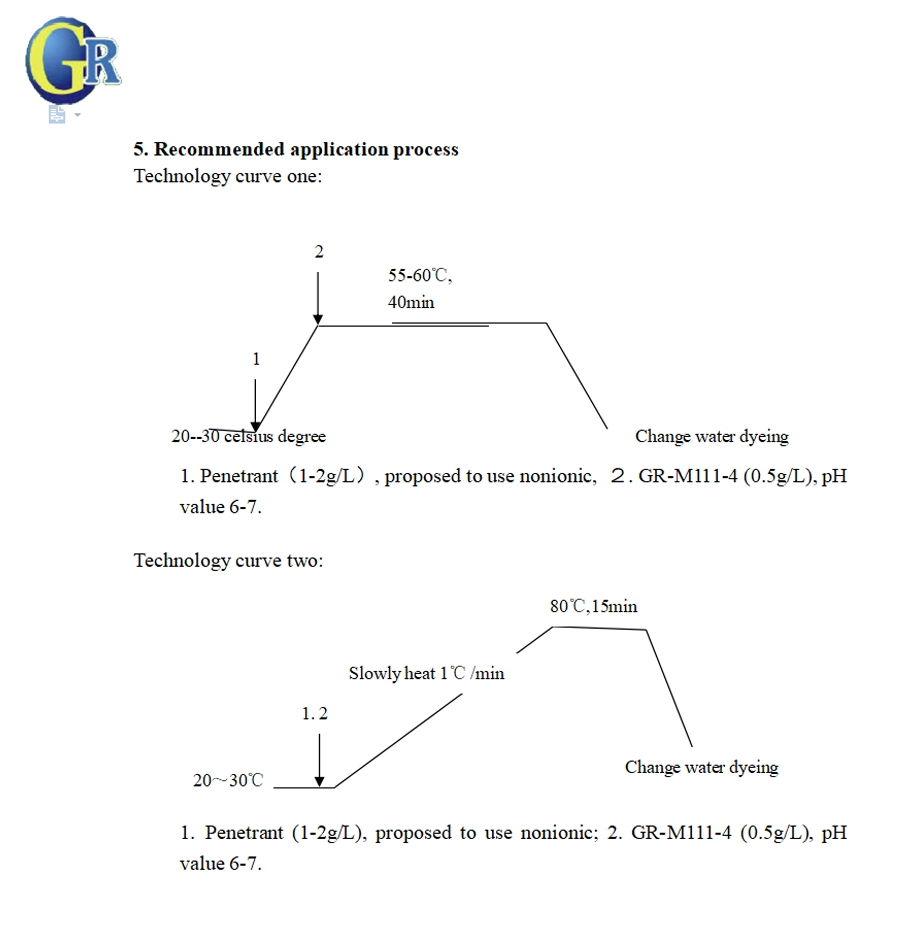

Technology curve one:

1. Penetrant(1-2g/L), proposed to use nonionic, 2. GR-M111-4 (0.5g/L), pH value 6-7.

Technology curve two:

1. Penetrant (1-2g/L), proposed to use nonionic; 2. GR-M111-4 (0.5g/L), pH value 6-7.

Shelf life

It can be stored for 3 months under 25 celsius degree, and more than 6months under 4-10 celsius degree.

Storage and transportation

Avoid exposure and rain. The warehouse should be kept cool, ventilated and dry.

Packaging

Standard packaging: 30kg/drum.

Suggest to store in 0-25°C airtight container, keep dry and avoid direct sunlight. Product has been disposed optimum stability. Exceed storage or poor conditions all will result in increasing dosage.

Safety

Nonflammable, can be soluble in water, safe and reliable when using. Do not contact with enzymes directly in operation, if direct contact with skin or eyes, rinse with water immediately.

function PH value range: 6.0-7.0

compared with traditional alkaline scouring, the advantages of enzyme scouring are as follows:

1. Scouring effect and Polishing effect together.

2. Eco-friendly, no damage to operators and equipments

- Low power, low water consumption, reduce TDS, COD, BOD index of wastewater, and reduce environmental pollution.

- Safe working environment, reduce damage to equipment.

- Have specific characteristics like enzyme, and only act on fabric impurities without damaging fibers.

- Improve dyeing performance, enhance levelness, upgrade color yield, reduce staining defective percentage;

- Fabric is soft,plump with glossy canvas and clear texture;

- Fabric shade will not change if making biological smooth finishing after dyeing;

- Improve security and stability of pretreatment for hemp/cotton blends, silk, viscose, bamboo fibers and cotton blends, and cotton fabric refining. It will be more perfect especially when used in scouring for some special sensitive fibers.

4. Shorten processing time, reduce costs

Merge enzyme desizing process and can be performed simultaneously with bio polishing process, also can bath with dyeing. Shorten processing time, improve production efficiency; the fabric weightlessness reduced, defect rate decreased;

- Reduce amount of acid, alkali (neutralization) and water (cleaning), save energy and water;

- Improve staining percentage, save dyestuffs;

- Relieve pressure of sewage treatment, reduce cost of sewage treatment.

Technology curve one:

1. Penetrant(1-2g/L), proposed to use nonionic, 2. GR-M111-4 (0.5g/L), pH value 6-7.

Technology curve two:

1. Penetrant (1-2g/L), proposed to use nonionic; 2. GR-M111-4 (0.5g/L), pH value 6-7.

Shelf life

It can be stored for 3 months under 25 celsius degree, and more than 6months under 4-10 celsius degree.

Storage and transportation

Avoid exposure and rain. The warehouse should be kept cool, ventilated and dry.

Packaging

Standard packaging: 30kg/drum.

Suggest to store in 0-25°C airtight container, keep dry and avoid direct sunlight. Product has been disposed optimum stability. Exceed storage or poor conditions all will result in increasing dosage.

Safety

Nonflammable, can be soluble in water, safe and reliable when using. Do not contact with enzymes directly in operation, if direct contact with skin or eyes, rinse with water immediately.