Basic Info.

Model NO.

DNY Belt sludge dewatering machine

Thickening System

Drum Thickening Belt Sludge Dewatering Machine

Electricity

Customized Belt Sludge Dewatering Machine

Belt Material

Polyester Belt Sludge Dewatering Machine

Designing

Belt Sludge Dewatering Machine with Thickner

Control

Pneumatic Belt Sludge Dewatering Machine

Belt Width

500/750/1000/1500 Belt Sludge Dewatering Machine

Price

Cheap Belt Dewatering Machine Manufacturer Price

Belt Qty

Double Belt Sludge Dewatering Machine

Transport Package

Seaworthy Belt Sludge Dewatering Machine

Specification

500/750/1000/1500 Belt sludge dewatering machine

Trademark

SINO Belt sludge dewatering machine

Origin

Henan Belt Sludge Dewatering Machine

HS Code

842129

Production Capacity

50 Belt Belt Sludge Dewatering Machine Set Month

Product Description

Belt Sludge Dewatering Machine for Municipal Industrial Wastewater Treatment

DNY-3 Series S.S.304 belt filter is a light-duty belt filter press, which is successfully developed on the basis of DNY Belt Filter Press. The difference is it adopts BELT THICKENING SYSTEM, but not Drum Thickening System. It is widely used in sludge dewatering of urban sewage treatment, chemical, oil refining, metallurgy, papermaking, tannery, food, coal-washing, printing & dyeing etc.. Belt filter press can continuous operate and with high degree of automation. It is energy saving, high efficiency and easy to maintain. It is an ideal equipment for sludge dewatering.

Features of DNY-3 Belt Filter Press:

1. The structure has a strong strength, a steady operation and low noise.

2. It is equipped with advanced concentration preprocessing equipment to flocculate slurry preferably and decrease running cost.

3. Belt thickening system is equipped to meet lower solid content materials.

4. It can dehydrate material sufficiently and make sure that the material will not overflow.

5. Dewatering rollers are arranged in a scientific way.

6. It works continuously from feeding to cake discharging.

7. It has high degree in automation.

8. It has a wide speed range for different concentrate needs.

9. It is equipped with reliable backwash device to ensure good dehydration effect.

10. The pneumatic tension and auto tracking device to ensure safe operation of filter belt.

11. Different filter belt can be selected based on various filtering material, the filter belt is of high precision.

12. Rotary drum thickener and belt thickener can be selected based on different material concentration.

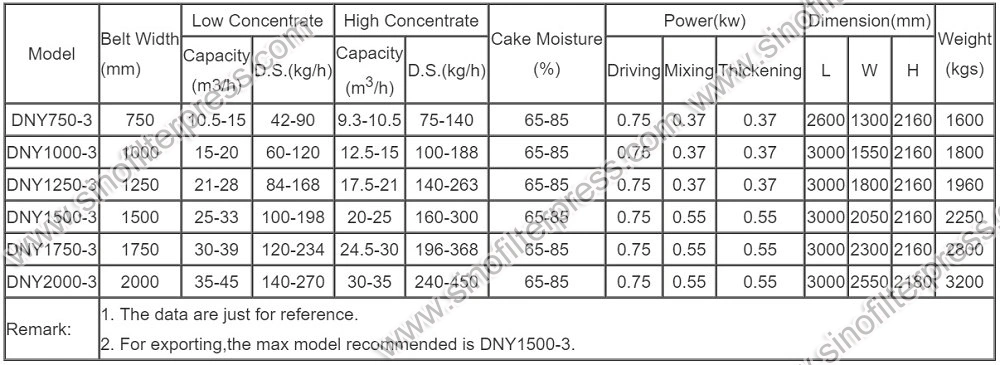

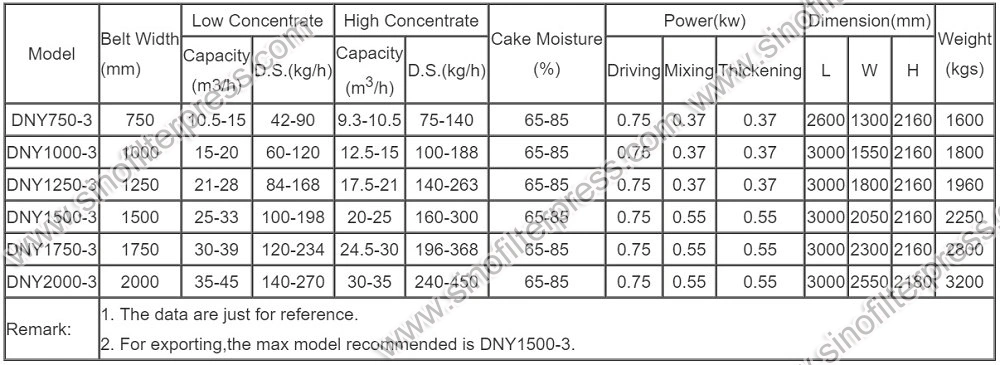

Specifications of DNY-3 Belt Filter Press:

Packing & Delivery of DNY-3 Belt Filter Press:

1.Delivery: around 4 weeks.

2.Packing: The packing is seaworthy packing.

After Sales Service of DNY-3 Belt Filter Press:

1. Documents supplied: Foundation/Circuit Diagram.

2. Site commissioning, installation and training service are valid.

3. Warranty: 13 months after B/L data.

Contact US:

2. It is equipped with advanced concentration preprocessing equipment to flocculate slurry preferably and decrease running cost.

3. Belt thickening system is equipped to meet lower solid content materials.

4. It can dehydrate material sufficiently and make sure that the material will not overflow.

5. Dewatering rollers are arranged in a scientific way.

6. It works continuously from feeding to cake discharging.

7. It has high degree in automation.

8. It has a wide speed range for different concentrate needs.

9. It is equipped with reliable backwash device to ensure good dehydration effect.

10. The pneumatic tension and auto tracking device to ensure safe operation of filter belt.

11. Different filter belt can be selected based on various filtering material, the filter belt is of high precision.

12. Rotary drum thickener and belt thickener can be selected based on different material concentration.

Specifications of DNY-3 Belt Filter Press:

Packing & Delivery of DNY-3 Belt Filter Press:

1.Delivery: around 4 weeks.

2.Packing: The packing is seaworthy packing.

After Sales Service of DNY-3 Belt Filter Press:

1. Documents supplied: Foundation/Circuit Diagram.

2. Site commissioning, installation and training service are valid.

3. Warranty: 13 months after B/L data.

Contact US: